What is CNC Machining?

What is CNC Machining?

There are many types of CNC machines. They all use a computer controlled machine tool to remove material from the workpiece.. Because of this computer control, CNC machining is much faster, more precise and accurate than conventional machining.

What is CNC Machining used for?

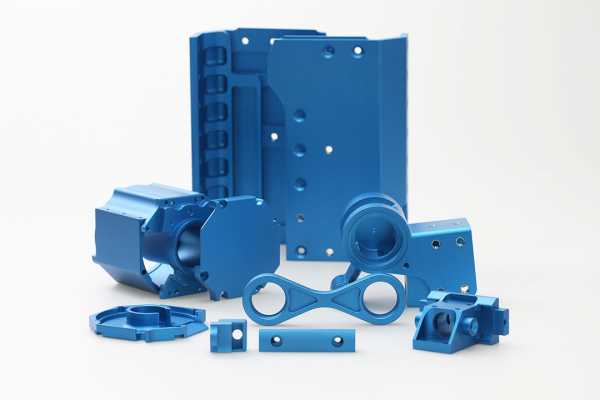

Our precision CNC machining services make complex finished parts and components as well as tools for plastic injection molding or pressure die casting. In addition, CNC manufacturing is used for secondary drilling, tapping, and milling operations on machined parts or parts made from other processes.

CNC machine tools come in many specialized types to perform all kinds of operations on raw stock. However, CNC mills are the most common and versatile multi-axis machines that we use at Star Rapid every day.

Our CNC Services

Our CNC Services

Star Rapid provides custom CNC milling and lathe services. Learn more about what services we offer.

CNC Turning ServicesCNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Star Rapid is your solution. Learn more about how we can support you. | CNC Turning ServicesCNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Star Rapid is your solution. Learn more about how we can support you. |

CNC Turning ServicesCNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Star Rapid is your solution. Learn more about how we can support you. | CNC Turning ServicesCNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Star Rapid is your solution. Learn more about how we can support you. |

CNC Turning ServicesCNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Star Rapid is your solution. Learn more about how we can support you. | CNC Turning ServicesCNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Star Rapid is your solution. Learn more about how we can support you. |

Star Rapid CNC Machining Service FAQ

-

Why choose CNC machining?

CNC machining is fast, accurate, and versatile. No other manufacturing solution produces end-use parts in any volume without the need to invest in hard tooling or expensive set-ups.

-

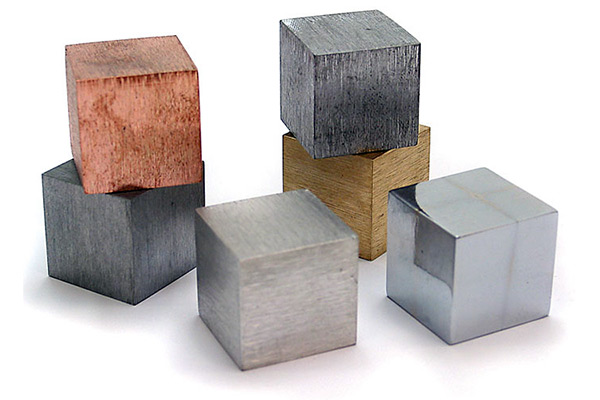

What raw materials can I use with CNC machining?

Almost any rigid solid can be machined, including mild and stainless steels, aluminum, brass, copper, magnesium, titanium, and many types of engineering plastics. Check out our list of frequently used materials.

-

What tolerances can I achieve with CNC machining?

Our standard tolerances are 0.05 microns, which is suitable for the majority of commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

Why Choose Star Rapid For CNC Machining Services

Why Choose Star Rapid For CNC Machining Services

Star Rapid’s CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

✓ Industry-Leading CNC machining equipmentImported 5-axis CNC machining centers running the most advanced AutoDesk and Vericut software. Exclusive Guhring cutting tools from Germany for the finest tool performance and longevity. | ✓ Intelligent pricing for every CNC machining projectOffering you a proprietary, patent-pending AI quotation algorithm. The power of machine learning gives you fast and accurate CNC machining quotes without guesswork. |

✓ Comprehensive raw material testing and verificationNo one in the industry offers more dependable positive material identification (PMI). You can proceed with full confidence that your parts will meet all of your material specifications and regulatory compliance requirements. | ✓ A full suite of finishing servicesMost CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part. |

Advantages Of CNC Machining Services

Advantages Of CNC Machining Services

One of the great advantages of CNC machining is that it works so well with so many different materials. These include mild and stainless steels, magnesium, brass, titanium, and even very hard alloys such as Inconel. In addition, rigid engineering plastics can be machined, as well as carbon fiber. All of these options give you even more design freedom. Learn more about our standard materials.

No matter what material you use, you need absolute confidence that it conforms to your specifications and regulatory requirements. That’s why we have a best-in-class material testing laboratory. We use positive material identification (PMI) to verify all incoming stock, and provide you with a full physical analysis. It’s the only way to be sure you get exactly the quality and performance you demand. CNC machining offers many advantages for product developers, including * Fast material removal * Tight tolerances and high precision * Excellent for making complex geometries * Versatile * Suitable for many different kinds of substrates * Unlimited volumes * Low investment in tooling * Fast turnaround * Parts are full-strength * Excellent surface finishes * Easily customized |

Star Rapid’s CNC Machining Projects

Star Rapid’s CNC Machining Projects

Agricultural Drone Sensor6061 aluminum is lightweight, strong, and resistant to corrosion. We worked with MicaSense to help them make CNC machined aluminum housings for their Altum agricultural sensor drone. Clear and colored anodizing along with laser etching produced a beautiful and durable part. Read more in this case study. | Electronic Cigarette CaseConsumerNext recently asked us to make a CNC milled aluminum case for a new kind of electronic cigarette. They needed a case in two different sizes, for both men and women, and in each size they wanted to try different anodized colors to test the market. To achieve this, we made some small batch runs in light gold, dark blue, light rose and warm grey. Read more in this case study. |

Custom Golf Club PutterCMBD is a custom golf club designer from the UK. They’re passionate about creating the ultimate putter for golf purists who will settle for nothing but the best. That’s why CMBD approached our team to help them machine their club head from high-quality Japanese D2 tool steel. Read up on our process and see the results in this case study. | IHMC Robotic ExoskeletonThe Institute for Human and Machine Cognition (IHMC) is a not-for-profit research institute developing robotic exoskeleton solutions to provide mobility for the physically impaired. The MinaV2 is CNC machined from aluminum and anodized for greater corrosion protection and scratch resistance. Learn more about our process and check out the finished Mina v2 when you read this case study. |

CNC Machining: Further Reading

CNC Machining: Further Reading

Improving CNC Machined Parts With Thin Film CoatingsStar Rapid exclusively uses Gühring end mills and cutters from Germany. An industry leader, Gühring applies special thin film coatings to their tools. These coatings increase tear and heat resistance, improve lubrication and tool hardness. For product developers this means less machine downtime, faster cutting speeds and superior surface finishes. Read more about why we use Gühring tools for our CNC machining services. | How To Choose The Right Material For CNC MachiningWhat is the right CNC machining material for you? To help you find the best solution for your needs, we’ve put together this guide on the advantages and applications of the most common materials we use every day to make prototypes and production parts. |

Request Your Free CNC Machining Quote Today

Request Your Free CNC Machining Quote Today

Our improved algorithm decreases CNC machining quotation times by up to 90%. Most quotes are delivered within 24 hrs., depending on project details. Your customer support partner will contact you directly about your CNC machining quote to ensure you’ve received it and to answer any questions you may have about your options.