Why Rapid Workshop for Medical Industry

Why Rapid Workshop for Medical Industry

Rapid Workshop offers reliable medical device prototyping and production, from simple to complex medical parts. With a combination of advanced technologies and excellent manufacturing expertise, we can bring your medical products to life in the most effective ways. Regardless of the part’s complexity, we can help you reach your goals through rapid prototyping, bridge tooling, and low-volume production.

|

|

Prototyping to Production Stages for Medical Industry

Prototyping to Production Stages for Medical Industry

Take advantage of top-level solutions for medical product development. Rapid Workshop offers expertly designed and engineered custom products with excellent durability and functionality. We offer these solutions in various stages, helping you meet your production goals.

- Prototyping

- Engineering Validation and Testing

- Design Validation and Testing

- Production Validation and Testing

- Mass Production

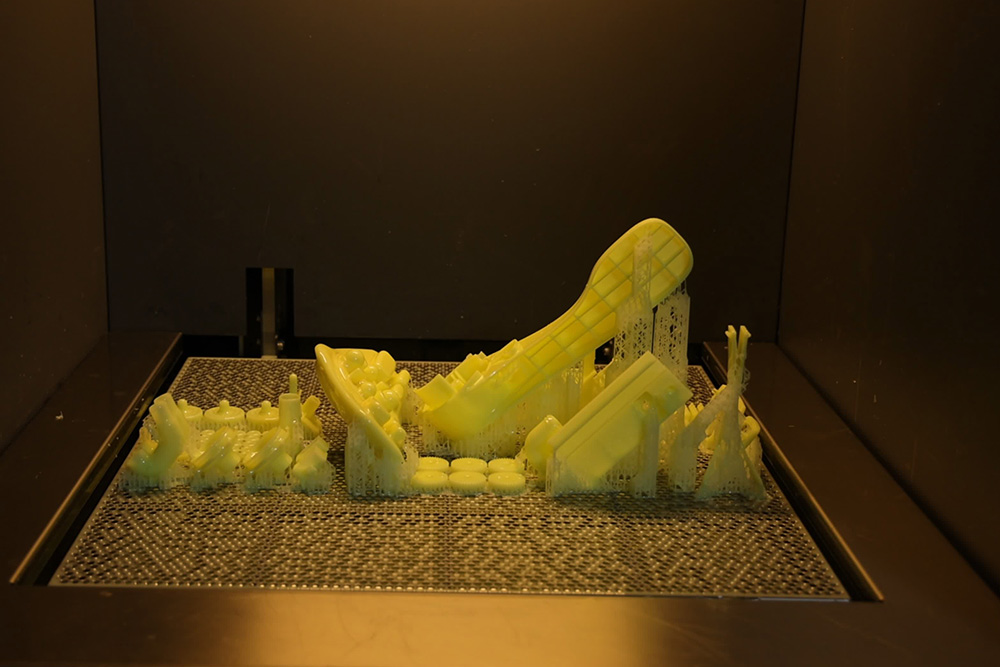

Prototyping

Create quality prototypes with production-grade material for early-stage development. Analyze your design and make the right design or material changes to prepare the medical prototypes for testing.

Prototyping

Upon analyzing your design file, our technicians will create prototypes to meet your design requirements. Your application will determine the materials and processes we will use to develop your component to look like the final product. This way, you can assess the specifications and carry out functional testing.

Quick Material and Design Changes

Precise Prototypes with Complex Geometries

Prototype Models Close to Final Component

Engineering Validation and Testing

Make quick and easy changes to functional medical device prototypes after engineering testing and validation of performance requirements.

EVT

We create functional prototypes similar to the final product. This way, you can easily identify design problems and rectify these issues. There may be a need for a number of changes to ensure performance requirements are met.

High-precision Prototypes Manufacturing

Optimum Design and Engineering Support

Optimized Designing and Material Choice

Design Validation and Testing

Validate your medical product’s performance, functionality, and look in the most effective manner. Make necessary design iterations to save production time and cost.

DVT

We offer top-notch designs for manufacturing feedback to help you analyze the performance and appearance of your medical prototypes. With a wide range of materials, finishes, and mechanical designs, we will create components with ideal end-use functionalities and finishes for market testing.

Quality Prototypes for Market Testing

Functionality and Appearance Validation

Quality Surface Finishing

Production Validation and Testing

Get your design ready for mass production using production-grade machining processes and an advanced quality management system.

PVT

Take control of your product design with feedback from the technical team. This way, you can assess the manufacturability and suitability of your product and make the final changes for more efficient production.

Verification of Manufacturing Processes

Rapid and Low-Volume Production Tooling

Quick Delivery of Quality Production Parts

Production-Grade Design Iterations

Mass Production

Migrate from product testing stages to the full-scale production of end-use medical parts. Adopt precise quality requirements and excellent manufacturing capabilities for high-quality products.

MP

We take your medical device production to the next level with our advanced manufacturing processes and engineering expertise. Our experts work to ensure your products meet quality and performance requirements at low costs and faster lead times.

-

High-Quality Medical Devices

-

Precision Machining with Tight Tolerances

-

Excellent Post-Processing Operations

-

In-Depth Quality Management System

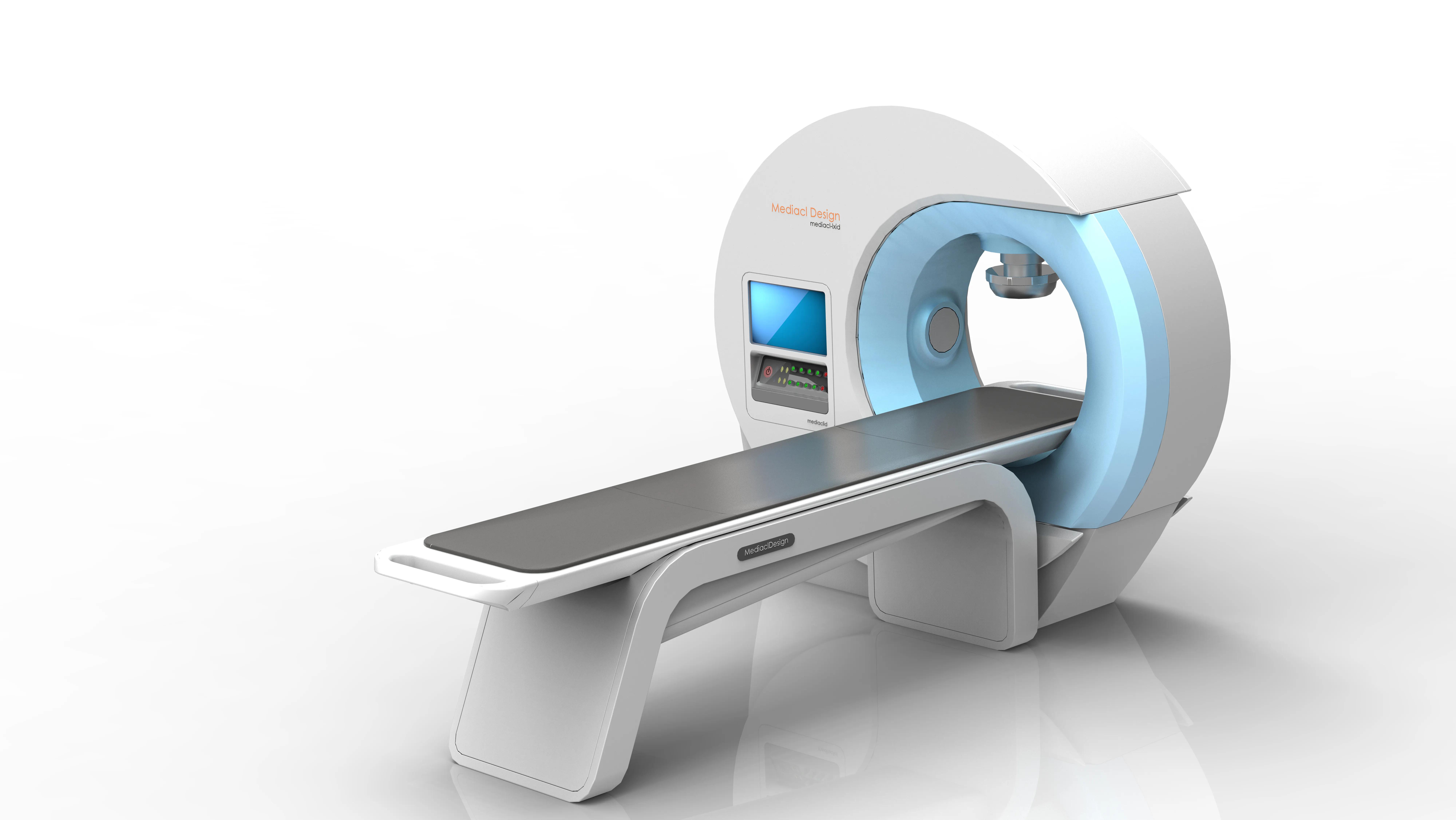

Medical Device Manufacturing

Medical Device Manufacturing

The medical industry depends on accurately and precisely created products to safeguard human health. Our ISO 13485 certification shows that we deliver precise, high-quality medical components that meet regulatory and quality standards. Enjoy reliable and professional medical device manufacturing solutions for custom products with the highest quality standards.

Medical Applications

Medical Applications

Our extensive production capabilities allow us to improve medical device production to serve many healthcare applications. Some of the applications include: * Handheld devices * Surgical instruments * Medical testing devices * Medical delivery systems * Ventilators * Implantable prototypes * Prosthetic components * Microfluidics * UV sanitation components |

Custom Prototypes and Parts for Medical Devices Industry

Custom Prototypes and Parts for Medical Devices Industry

Several leading medical device companies depend on our outstanding medical prototyping and production solutions for their custom medical parts. Our manufacturing capabilities and quality management system ensures that we produce components that meet performance and safety standards.

Let's Start A New Project Today

Let's Start A New Project Today

Explore More Industries We Support

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries. Click on the link below to know more.