Why Choose Us for Automotive Manufacturing

Why Choose Us for Automotive Manufacturing

At Rapid Workshop, we focus on prototyping and production of industry-standard automotive parts. Our combination of manufacturing and engineering expertise and advanced technology ensures we deliver high-quality parts regardless of complexity. We also guarantee parts that stand the test of time while ensuring you reach your production goals and accelerating your automotive product development.

Prototyping and Production Solutions for Automotive Industry

Prototyping and Production Solutions for Automotive Industry

Get reliable solutions for the automotive industry’s new product development. Our custom automotive parts are expertly engineered to meet and surpass industry standards in durability and performance. Our solutions cut across different stages of production to meet your manufacturing goals.

- Prototyping

- Engineering Validation and Testing

- Design Validation and Testing

- Production Validation and Testing

- Mass Production

Prototyping

Prototypes signal the early stage of automotive product development. At this stage, you test your designs, make design changes where necessary, and choose the right material for your automotive part.

Prototyping

At Rapid Workshop, we use your design files and product requirements for automotive prototyping to create a working prototype for you. Depending on your design needs, we will develop parts identical in appearance and functionality to the final product. Our aim here is to allow you to examine and test the part to ensure it meets your specification. We also guarantee a fast turnaround on prototypes.

Apply changes quickly and at a low cost to materials and designs

Prototypes with complex geometries are also detailed

The models created are identical to the final product

Engineering Validation and Testing

Make performance-based iteration quickly and efficiently, ensuring prototype functionality meets standard requirements.

EVT

At Rapid Workshop, we produce functional prototypes, making it easier to identify and avoid risks in design. Although this process often requires several design iterations, it ensures the final prototype produced meets all functional and performance requirements.

24/7 design and engineering support

Manufacturing of precision parts

Material properties optimization for customized designs

Design Validation and Testing

This stage involves evaluating and validating part functionality, appearance, and performance using different materials as well as surface finishing options. In other words, this test helps ensure the part meets your specific design and product needs.

DVT

At Rapid Workshop, we have a wide range of materials, and finishing options that match your uniquedesign requirements. Parts with aesthetic finishes in this stage always have end-use functionality and are ready for market testing.

Long-lasting and high quality surface finishing

Appearance and performance evaluation and validation

Top-notch parts for consumer appraisal and market testing

Production Validation and Testing

This is the final phase before the onset of mass production. PVT involves preparing the design for full-scale production using advanced-quality control and production-grade manufacturing capabilities.

PVT

At Rapid Workshop, we work with you closely at this stage to ensure you achieve your production goals. We rely on your feedback and allow you to make final changes to your model to ensure optimal manufacturing. At this stage, we also work with you to set up the product supply chain.

Verify manufacturing processes

Tooling for low-volume production

Quick delivery of production quality components

Evaluate production ready parts for functionality

Mass Production

This is the next stage after product testing and involves the mass production of end-use parts. At this stage, rapid delivery of final products and precision in quality requirements is key.

MP

At this stage of the automotive production process, Rapid Workshop mass produces your parts using a combination of advanced manufacturing machines and processes and professional engineers. Combining these elements helps ensure product quality and yield remain optimal while reducing production costs and lead times.

Meticulous inspection for quality control

Top quality custom parts

Secondary operations to meet optimal surface requirements

Precision machined parts always meet tight tolerances

Automotive Manufacturing Capabilities

Automotive Manufacturing Capabilities

We offer top-quality services at different stages of the production cycle, from prototyping to mass production. At Rapid Workshop, we guarantee you road-worthy automotive parts with high quality. Furthermore, our quality control process ensures you get parts that meet your quality requirements at a low cost.

Automotive Applications

Automotive Applications

At Rapid Workshop, we improve the production rate of a wide range of automotive components. Common automotive applications we undertake include.

* Lighting features and lenses |

Custom Prototypes and Parts for Automotive Companies

Custom Prototypes and Parts for Automotive Companies

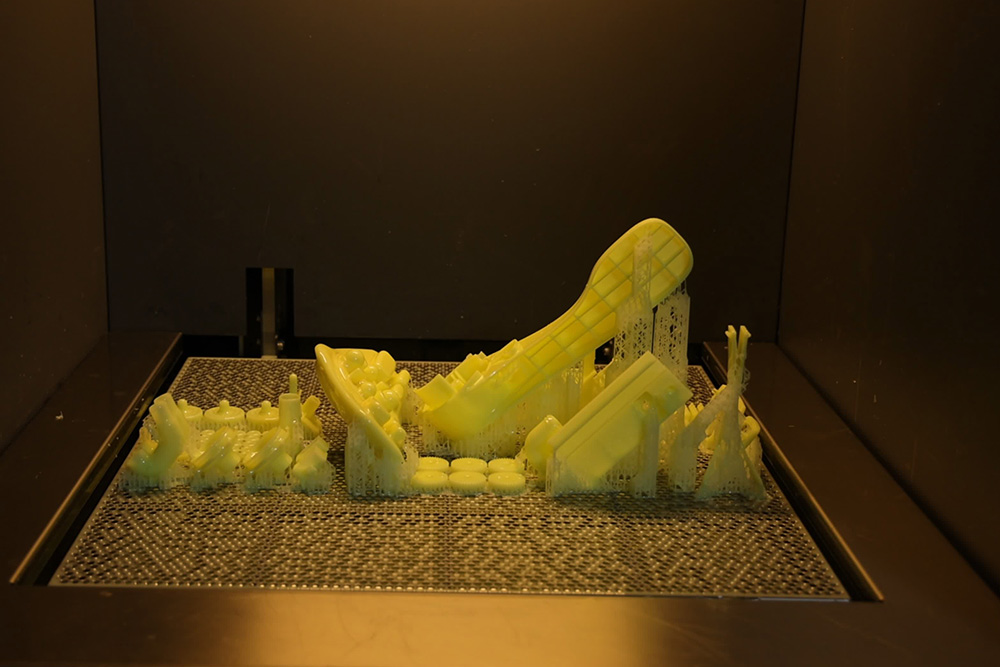

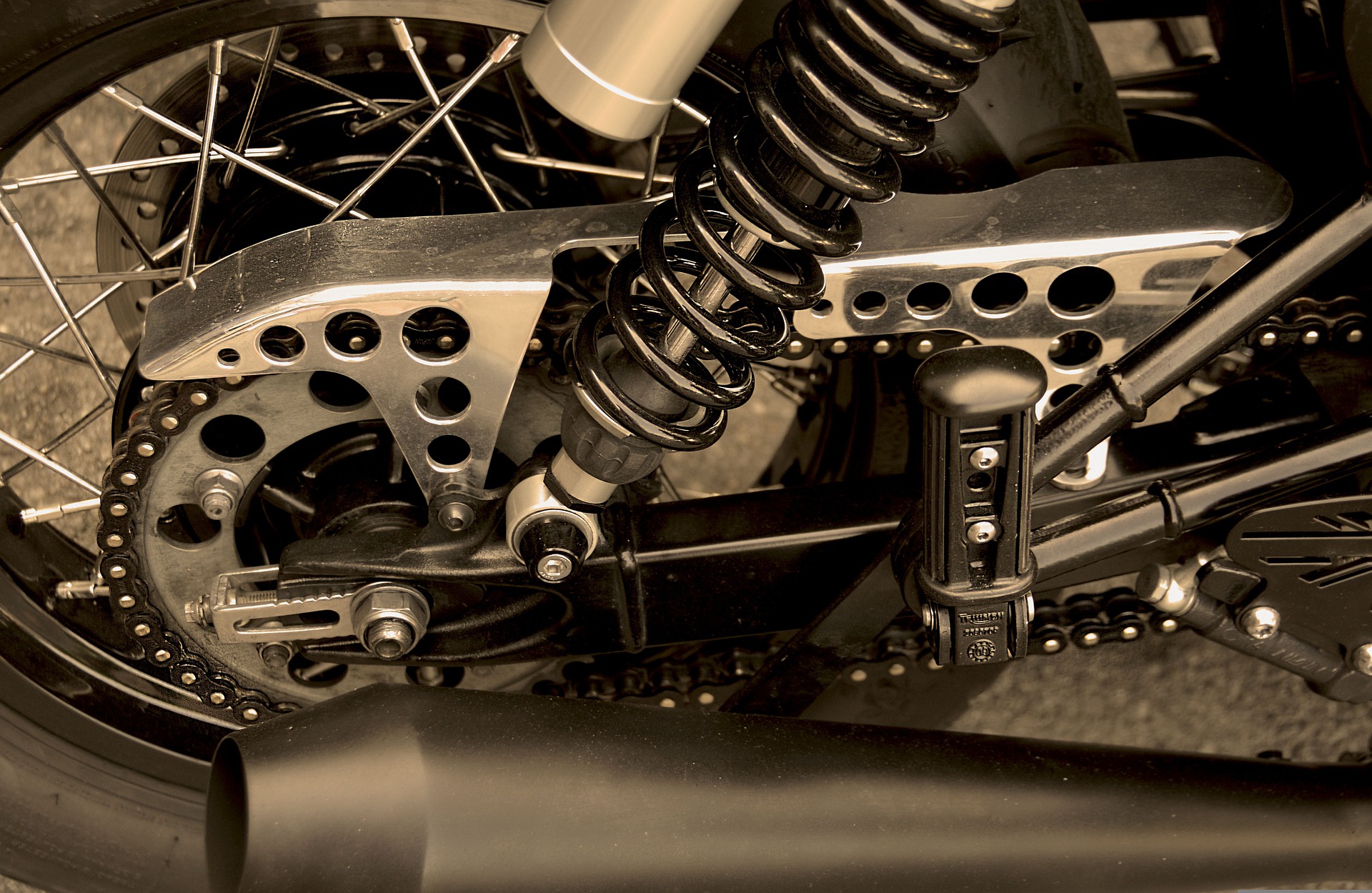

Businesses and automotive parts companies trust our manufacturing solutions to produce their custom automotive parts. They rely on us for all the stages of production, from prototyping to mass production, as they know we produce parts that meet industry performance and safety standards. Below is our gallery, which shows precision-machined automotive prototypes and mass-produced parts.

Let's Start A New Project Today

Let's Start A New Project Today

Explore More Industries We Support

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries. Click on the link below to know more.